News

High-concentration ammonia nitrogen wastewater treatment and recycling technology

Cutting-edge environmental information sharing

The atmosphere is rich in ammonia, which is a sufficient and necessary condition for frequent haze explosions!

In the winter of 2017, the average concentration of PM2.5 in Beijing-Tianjin-Hebei and surrounding areas was 85 micrograms per cubic meter, of which nitrate, sulfate, and ammonium salts accounted for 19%, 12%, and 11%, respectively, revealing the atmospheric PM2 in Beijing-Tianjin-Hebei. 5 Chemical characteristics have changed significantly, with similar results measured in the winter of 2018. The rapid generation of components such as nitrate, sulfate, and ammonium has boosted the explosive growth of PM2.5. The ammonium salt is mainly produced by the neutralization reaction of ammonia (NH3) with sulfur, nitrogen and other acidic substances; the concentration of ammonia in the atmosphere of Beijing, Tianjin, Hebei and surrounding areas is significantly higher than that of developed countries and regions such as the United States, which is in an ammonia-rich state.

In recent years, the concentration of SO2 in the region has continued to decline, and the concentration of NH3 in the atmosphere has increased without decline, which is more conducive to the formation of nitrates.

Part1 Overview of ammonia nitrogen wastewater source and treatment technology

Overview of ammonia nitrogen wastewater source and main treatment technology

The main methods of ammonia nitrogen wastewater treatment:

Biochemical method, inflection point chlorine method, ion exchange method, chemical precipitation method (MAP), membrane method, air stripping method, steam stripping method, etc.

| Method | Ammonia nitrogen concentration | Product / Recycled Product | Scope and advantages / disadvantages | Industry | |

| 1 | Nitrification / Denitrification (Biochemical) | Mid Lo | Nitrogen, not recycled | Suitable for wastewater with large water volume and low concentration, large investment area and low operating cost | Municipal |

| 2 | Ion exchange method | Mid Lo | Ammonium salt solution | High water inlet requirement and good water outlet effect | Inorganic chemical industry |

| 3 | Membrane separation | Mid Lo | Ammonium salt solution | High water inlet requirement and good water outlet effect | Inorganic chemical industry |

| 4 | MAP precipitation method | High | Magnesium ammonium phosphate | Fertilizer can be made, high running cost | Chemical industry |

| 5 | Inflection point chlorine method | Low | Not recycled | Simple process and high running cost | Advanced processing |

| 6 | Air stripping | Mid High | Ammonium salt solution | Secondary pollution, poor effluent effect | Chemical industry |

| 7 | Steam stripping | High | Ammonia / Ammonia | The process is complicated, and ammonia can be recycled | Chemical industry |

Part2 High-concentration ammonia nitrogen wastewater treatment and resource utilization technology

| NH4+-N | Inorganic ammonia nitrogen in water exists in the state of ammonia ion (NH4 +) and free ammonia (NH3). The equilibrium relationship between the two is as follows: NH3 + H2O ⇌ NH4 ++ OH- |

| pH and temperature | The balance of NH4 + and NH3 in wastewater is greatly affected by pH and temperature. Generally, the higher the pH, the higher the temperature, and the greater the proportion of free ammonia NH3 in the water. |

| Deamination principle | When the wastewater is under alkaline conditions, the equilibrium shifts to the left and the proportion of free ammonia increases. If steam is passed into the wastewater, the free ammonia will be transferred from the wastewater liquid phase to the gas phase with the steam flow, thereby achieving the removal of ammonia nitrogen NH3 · H2O = H2O + NH3 ↑ (high temperature). |

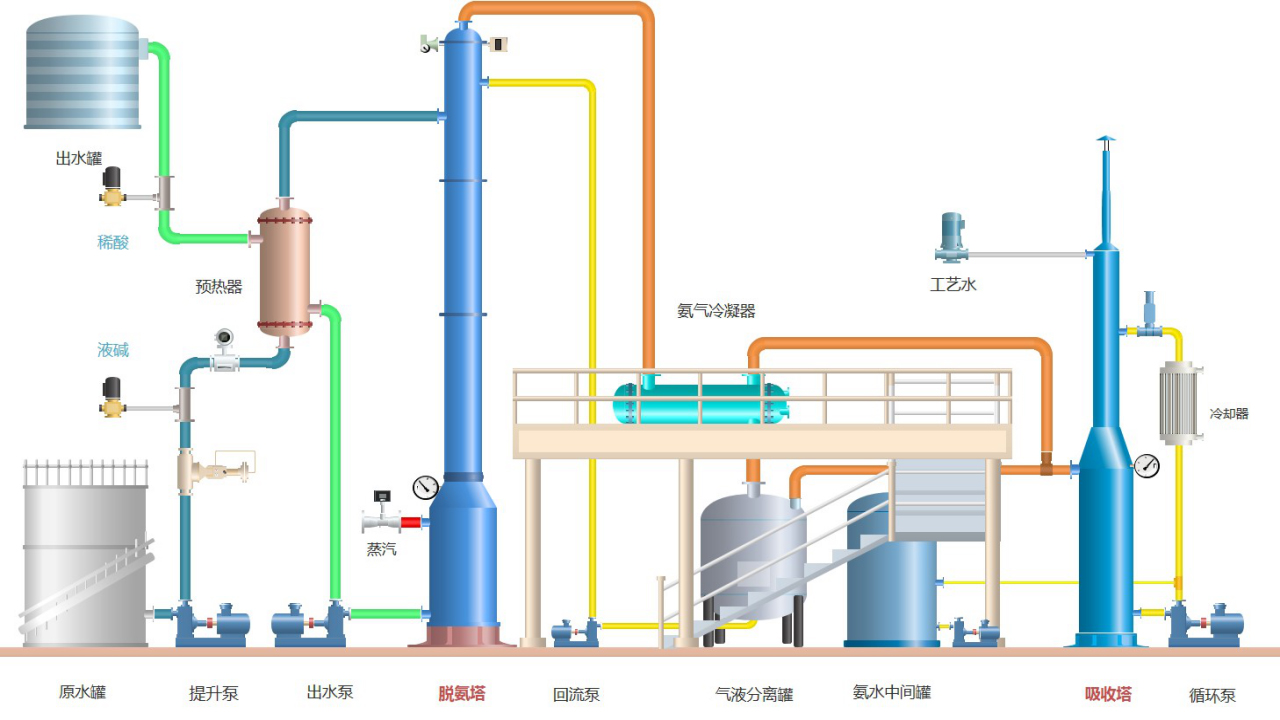

Schematic diagram of the process of recovering ammonia water by stripping ammonia removal at atmospheric pressure

Schematic diagram of the process of recovering ammonia water by negative pressure stripping and deamination

core advantages

| (1) High deamination efficiency: high efficiency and precision U-shaped trays: our invention patented technology, U-shaped diversion jet trays with large flux and low resistance drop; greatly improve the separation efficiency of deamination tower; reduce equipment Cost; the one-time discharge standard (≤15mg / L) for the treatment of ammonia nitrogen wastewater, with a minimum of 5mg / L or less. (2) Low operating cost: The steam consumption is ≤110 kg / ton of water, which can save more than 25% compared with the domestic conventional deamination system. (3) Large operating flexibility: The processing capacity can be adjusted from 80 to 110%. (4) Advanced self-control level: visual display of working condition data, automatic one-button switching by hand; automatic operation of real-time tracking, interlocking, adjustment, and recording. (5) Rich case experience: The technology is mature and reliable, with multiple successful cases, equipment serialization, complete set, modularization, and automation. (6) Excellent project team: Has an experienced design, installation, commissioning, and after-sales team. | Multiple patents, serialization, complete sets, automation

装置模型 |

Part3 project performance

Typical industries: ternary lithium battery industry, non-ferrous metals, coal chemical industry, pesticides, medicine, glass, chlor-alkali, photovoltaic, etc.

Partial performance list in the past 3 years: glass / photovoltaic / chemical industry

| Number | Client's name | Industry | Scale | Quantity | Location |

| 1 | Hebei Dejin Glass Co., Ltd. | Float glass | 300t / day | 1set | Hebei · Shahe |

| 2 | Sichuan Hengtai Environmental Technology Co., Ltd. | Photovoltaic energy | 240t / day | 1set | Sichuan Mianyang |

| 3 | Shanghai Bizhou Environmental Technology Co., Ltd. | Photovoltaic energy | 30t / day | 1set | Yangzhou, Jiangsu |

| 4 | Xuancheng Yabang Chemical Co., Ltd. | Chemical pigment | 1000t / day | 1set | Xuancheng, Anhui |

| 5 | Jilin Cornell Chemical Industry Co., Ltd. | Coal chemical industry | 600t / day | 1set | Jilin Jilin |

| 6 | Lianhua Technology Co., Ltd. | Chemical Pharmaceutical | 30t / day | 1set | Taizhou, Zhejiang |

| 7 | Hubei Yuanda Life Science and Technology Co., Ltd. | Chemical Medicine | 150t / day | 1set | Huangshi, Hubei |

| 8 | China Catalyst New Materials Co., Ltd. | Catalyst | 120t / day | 1set | Dalian, Liaoning |

| 9 | Shandong Wendeng Xijiao Thermal Power Co., Ltd. | Chlor-Alkali Chemical | 840t / day | 1set | Shandong Wendeng |

| 10 | Wuxi Fortune Pharmaceutical Co., Ltd. | Chemical Pharmaceutical | 300t / day | 1set | Jiangsu Wuxi |

List of partial performance in the past 3 years: ternary precursor cathode materials industry for power lithium batteries

| Number | Client's name | Industry | Scale | Quantity | Location |

| 1 | New Times Group Zhejiang Energy New Materials Co., Ltd. | Ternary cathode material for lithium battery | Phase I500t / day Phase II 1000t / day | 2 sets | Shangyu, Zhejiang |

| 2 | Guangdong Fangyuan Environmental Co., Ltd. | Ternary cathode material for lithium battery | 600t / day | 1set | Jiangmen, Guangdong |

| 3 | Henan Kelong New Energy Co., Ltd. | Ternary cathode material for lithium battery | Phase I500t / day Phase II 1300t / day | 2sets | Xinxiang, Henan |

| 4 | Polyfluorochemical co., Ltd. | Ternary cathode material for lithium battery | 30t / day | 1set | Jiaozuo, Henan |

| 5 | Jiangxi Ganfeng Lithium Industry Co., Ltd. | Ternary cathode material for lithium battery | 300t / day | 1set | Jiangxi · Xinyu |

| 6 | Yuyao Fengyuan Power Supply Co., Ltd. | Ternary cathode material for lithium battery | 300t / day | 1set | Shaoxing, Zhejiang |

| 7 | Meishan Shunying Power Battery Material Co., Ltd. | Ternary cathode material for lithium battery | 100t / day | 1set | Sichuan · Meishan |

| 8 | Chizhou Xinen New Material Technology Co., Ltd. | Ternary cathode material for lithium battery | 300t / day | 1set | Chizhou, Anhui |

| 9 | Hunan Jinfuli New Material Co., Ltd. | Ternary cathode material for lithium battery | 300t / day | 1set | Changsha, Hunan |

| Unit | Xuancheng Yabang Chemical |  |

| Scale | 1200 tons / day ammonia nitrogen wastewater | |

| Water | Ammonia nitrogen concentration is about 7000mg / L | |

| Effluent | Ammonia nitrogen≤15mg/L | |

| Recycle | ≥20% ammonia | |

| Industry | Chemical Industry (Pigment) |

TEL:0510-68991888

Address: No. 19 Xingli Road, Economic and Technological Development Zone, China

Web:www.jsjrep.com

Fax:0510-68991866

扫码浏览手机站

Copyright © 2024 Jiangsu Jinrun Environmental Production Engineering Co., Ltd. 苏ICP备19049893号-1